Our Build Process

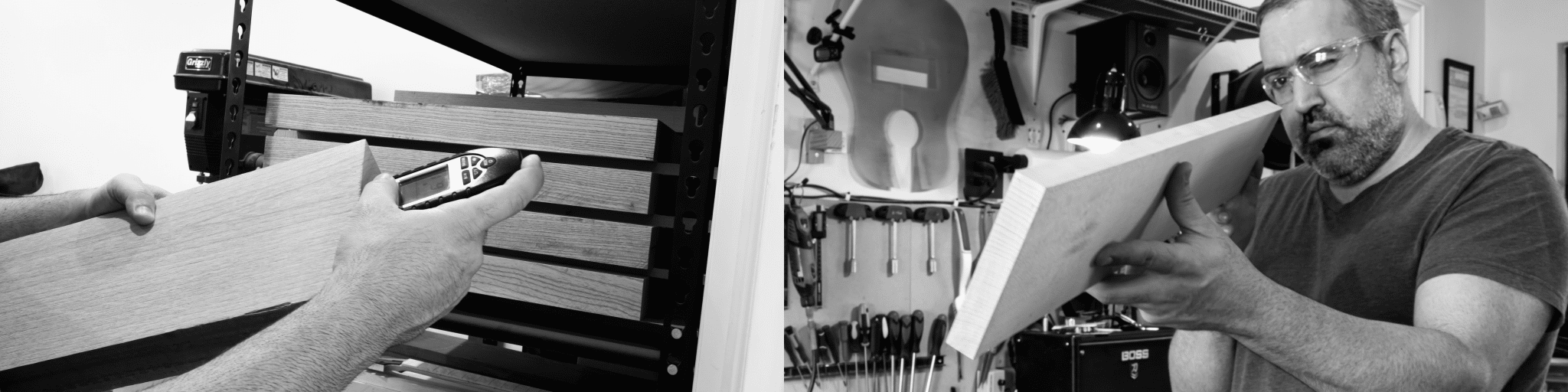

Wood selection

At AnkaCustom, we take great care in selecting the right pieces of wood for our guitars and basses. We ensure that there are no cracks, incorrect moisture levels, hollow streaks, imperfections, or big knots in the wood that we select. Additionally, we pay close attention to the grain pattern of the wood, choosing pieces with beautiful and unique patterns whenever possible. This careful selection process is essential to creating the high-quality instruments that we are known for.

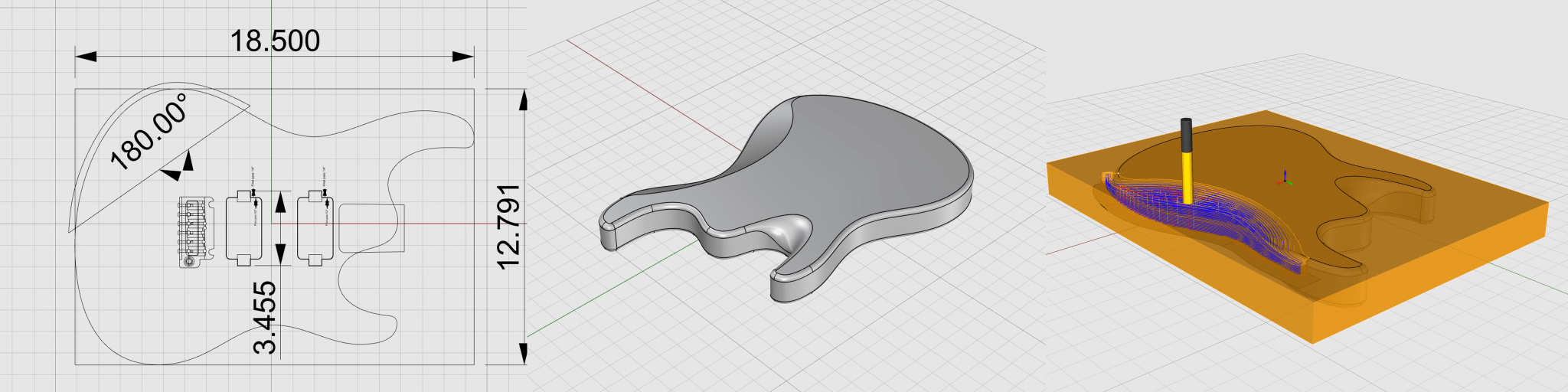

Design and Programming

Once the wood has been carefully selected, we move on to designing and programming the guitar. This involves creating all of the contours, calculating the dimensions, and selecting the most efficient strategies for cutting and carving the wood. Our team uses CAD/CAM software to design the guitar and create toolpaths that guide our precision machinery in the cutting and carving process. Through this process, we are able to achieve precise and consistent results for each instrument we create, ensuring that every detail is just right.

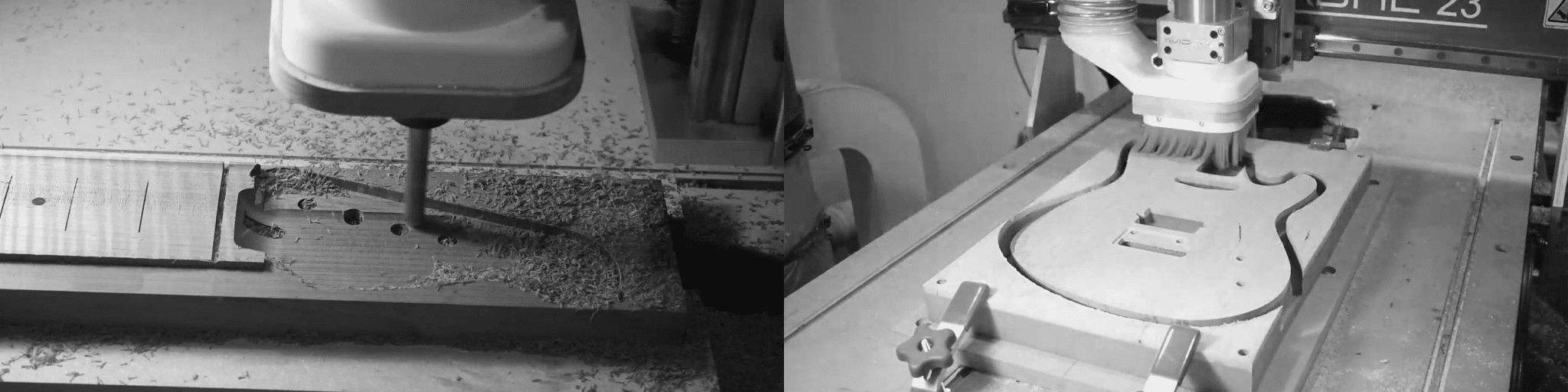

Rough Cut

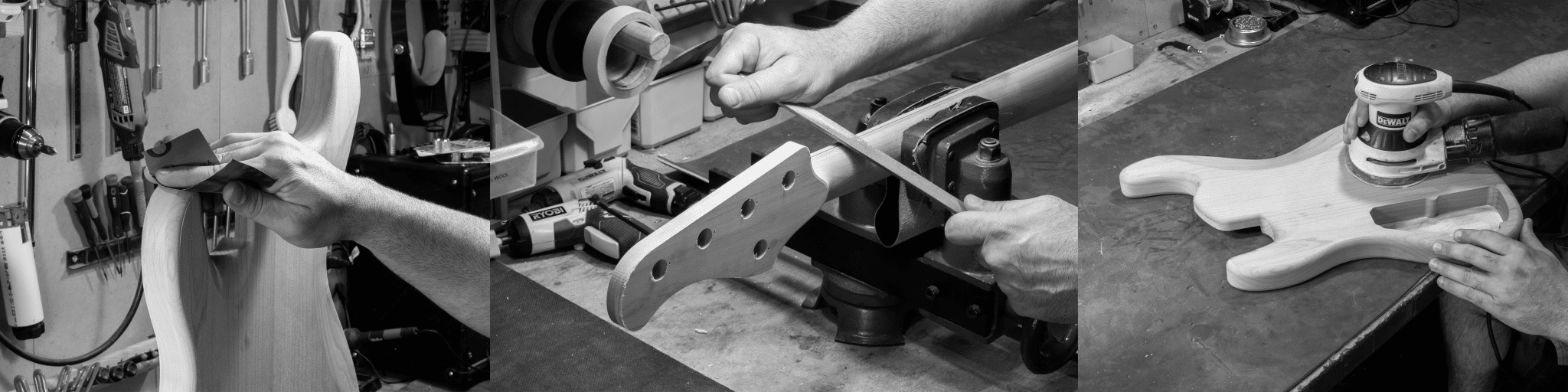

Shaping and Final Sanding

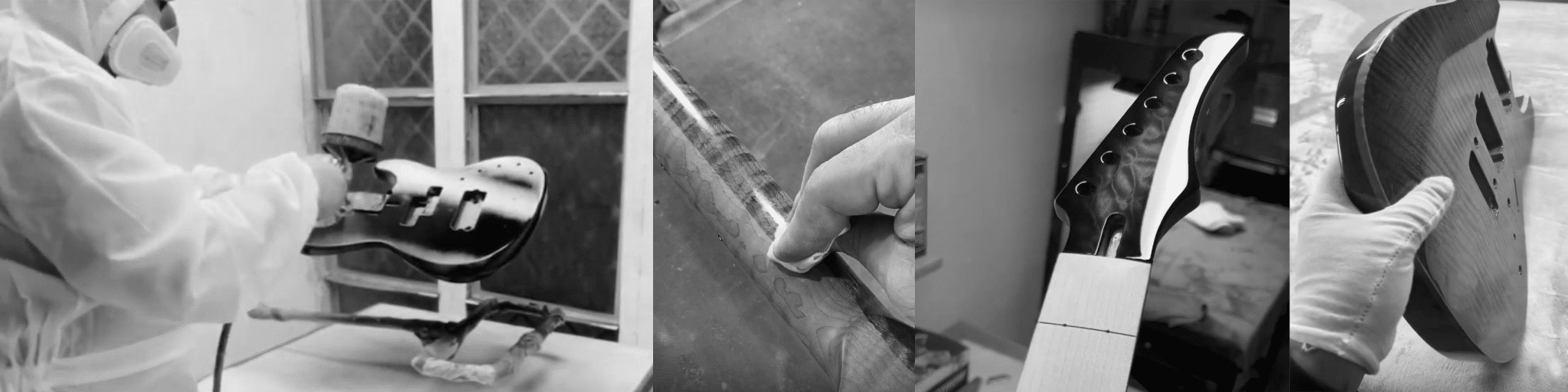

Finishing

This is the final step of the building process where we apply various finishes to the wood in order to protect and enhance its appearance. We offer a range of finishes such as high gloss, satin, stained, translucent, sparkles, pearls, solid, and many more to meet the diverse needs and preferences of our customers. Polyester is our number one choice for clear coats since it is the hardest, most durable, and scratch-resistant option available. Our team takes great care in prepping the wood surface before applying the finish to ensure a flawless and durable result.

Final Assembly and Testing

At this stage of the process, all the pieces of the guitar or bass come together. We put the strings on and assemble all the electronics. We take the time to test everything to make sure it works perfectly. Then, we install the nut, the hardware, we level the frets, and do a full setup of the guitar, adjusting the action, intonation, and truss rod to ensure it plays beautifully. Finally, we play the guitar ourselves to make sure everything is perfect and ready for delivery to its new owner.